Cool induction scheme

With our comprehensive onboarding phase including factory visits, IT and product training courses, team-building and much more, you will transition seamlessly into your new career and feel at home straight away with our group of companies.

Top support

Your mentor has your back as you develop your career and will support you with any concerns that may arise during your course. A coordinator is on hand to help organise your projects during the practical phase, while your specialist advisor can provide practical advice and assistance with projects and practical phases.

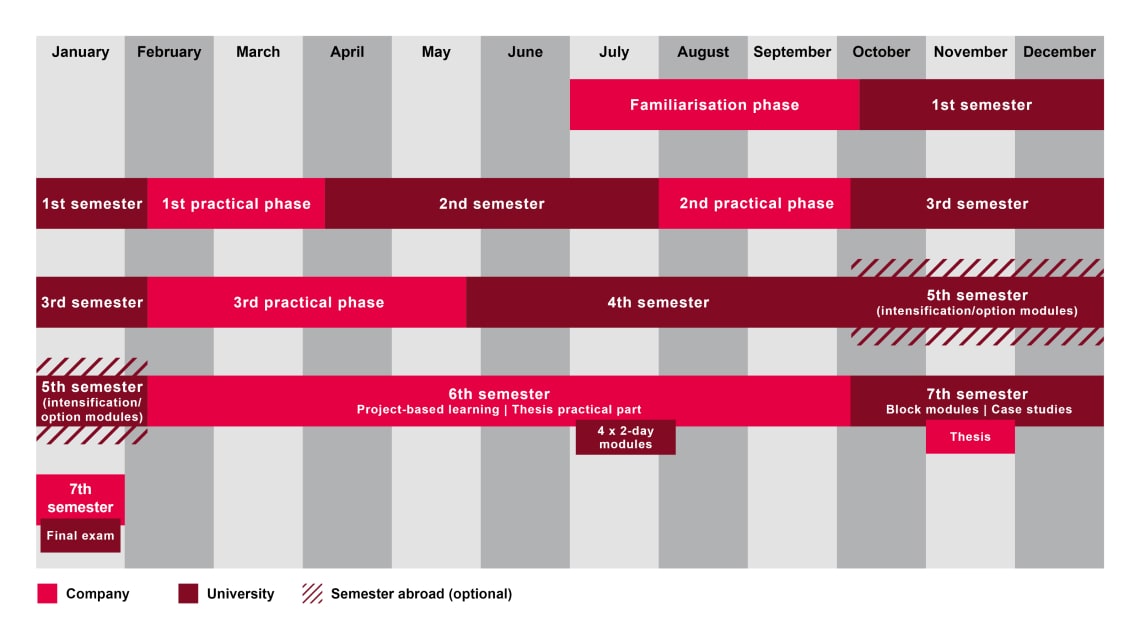

Insights into national and international departments

In every course, you can build on your theoretical knowledge with practical placements in selected departments. These practical phases, whether national or international, are arranged in collaboration with your mentor and coordinator to provide in-depth insights into different areas of the group.

PraticalPlus phase

The PracticalPlus project is one of the highlights of your first practical phase. Together with your fellow students at the Friedhelm Loh Group, you will embark upon an interdisciplinary project. As you are working, you are also preparing to give a presentation at the end of the project.

Networking

Twice a year, you convene with your fellow students for networking and exchange with various individuals, including a top manager from the Friedhelm Loh Group. Afterwards, there will be plenty of time for a convivial meal and conversation.

International assignments

As part of your course, you have an opportunity to complete a project or a semester abroad. As well as being an opportunity to meet colleagues from more than 95 countries around the globe and forge new contacts, this is also your chance to build on your intercultural skills and gain valuable experience.

Coaching

A coach is on hand throughout your degree course to provide development coaching.

Your own laptop for university and in-house work

Before the course begins, you will receive your own IT equipment which is available to use for the duration of your degree program.